COMPARISON OF DIAGNOSTIC SYSTEM CAPABILITIES

| WORKFLOW PARAMETERS THAT ARE DEFINED | PMI SYSTEM | DEPAS 4.0, 5.0 |

|---|---|---|

|  |

|

| Pressure sensor | • | • |

| Pressure diagram vs crank angle (time) vs volume | • | • |

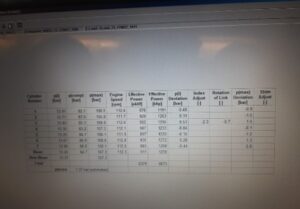

| Basic working process parameters: Revolution (RPM), Pmax (mean, max, min), Pcomp, Pignition, IMEP, IPower, Pexh | • | • |

| Derivative pressure diagram | • | |

| Vibro sensor | • | |

| Vibro diagrams analysis | • | |

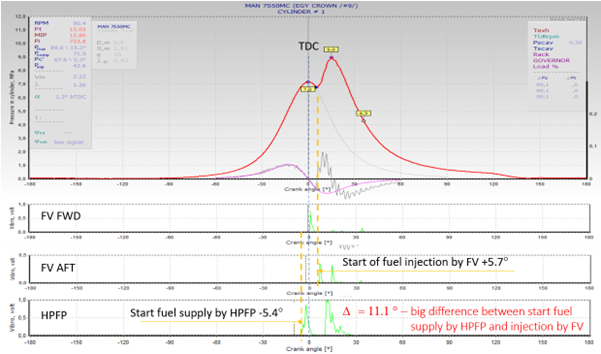

| Fuel injection timing (fuel injection advance angle and phase duration) | • | |

| Diagnostics of technical condition of injection equipment | • | |

| Valve timing angles | • | |

| Diagnostics of the technical condition of the gas distribution mechanism | • | |

| FFT spectrum, wavelet | • | |

| Turbocharger analysis | • | |

| TDC determination | TDC-sensor | Software |

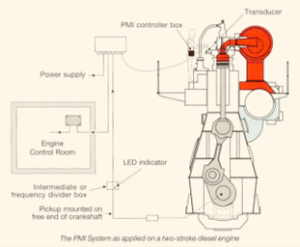

The analysis of data obtained from the pressure sensor is the same for both systems.

In the DEPAS system, unlike the PMI, there is the possibility of vibration diagnostics of the fuel supply equipment, the valve timing mechanism and the turbocharger.

| PMI SYSTEM | DEPAS 4.0, 5.0 | ||

|---|---|---|---|

|  |  |

|

|  |

||

RELATIONSHIP OF PERIODIC DIAGNOSTICS WITH ELIMINATION OF DEFECTS AND REDUCTION OF FUEL CONSUMPTION

Periodic diagnostics of the technical condition of the cylinder-piston group, high-pressure fuel equipment and valve timing mechanism allows for timely detection and elimination of defects that negatively affect the efficiency and stability of the working process and the quality of fuel combustion in the cylinders. Timely elimination of defects, restoration of the actual compression ratio, optimization of fuel timing and valve timing ensure an increase in the working cycle power without increasing the fuel supply, promote more complete combustion and, as a result, a decrease in specific fuel consumption at a given load.

SFC – specific effective fuel consumption, g/kWh; Gh – mass fuel consumption, kg/h; Pe – effective engine power, kW; QH – lower heating value of fuel, kJ/kg (for example, for MDO ≈ 42700 kJ/kg); η – engine efficiency (~0.45–0.54 for modern two-stroke diesel engines).

In addition, regular maintenance checks significantly reduce the risk of emergency situations, including sudden loss of power, engine failures and blackouts, which can lead to the vessel being stopped at sea. Although such events are difficult to calculate accurately, their prevention is critical for the safety of the vessel and crew, and also allows the shipowner to avoid significant financial losses associated with emergency repairs, delays and reputational risks.

Thus, the implementation of a system of regular parametric diagnostics of the working process of marine engines including the main systems, is a means of increasing fuel efficiency and an important element of the overall strategy for managing the operational reliability and safety of a marine vessel.